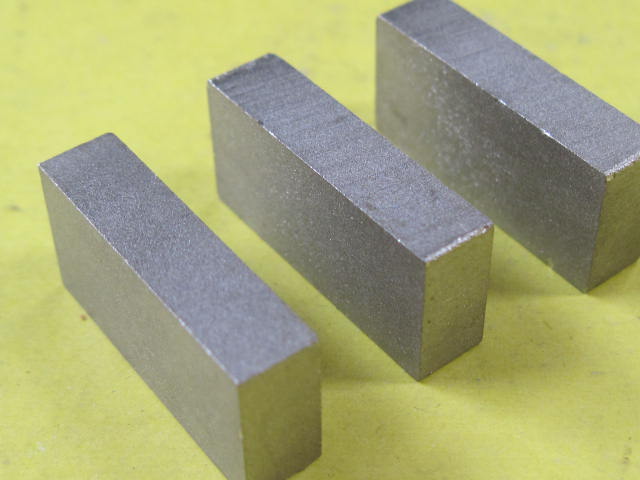

SmCo5 Magnets

SmCo5 magnets have the advantages of high heat resistance (up to 300°C), low temperature resistance (below absolute zero, -273°C), market-sensitive price, high corrosion resistance, high resistance to demagnetization, and high magnetic strength. It is ideal for industrial applications. SmCo magnets can be brittle and work best in applications that do not require direct impact.

Product Information

The SmCo5 magnets are proportioned with the metals samarium, cobalt and praseodymium. It has a (BH) maximum range of 16 to 25 and a maximum operating temperature of 250°C. A samarium cobalt magnet is a rare earth magnet, and also a powerful permanent magnet made from an alloy of samarium and cobalt. They are generally similar in strength to neodymium magnets, but have higher temperature ratings and higher coercivity. They are brittle and crack and crumble easily.

Features

SmCo5 magnets have the advantages of high heat resistance (up to 300°C), low temperature resistance (below absolute zero, -273°C), market-sensitive price, high corrosion resistance, high resistance to demagnetization, and high magnetic strength. It is ideal for industrial applications. SmCo magnets can be brittle and work best in applications that do not require direct impact.

Attributes

– SmCo5 magnets are extremely resistant to demagnetization.

– They have good temperature stability (maximum use temperatures between 250 °C (523 K) and 550 °C (823 K); Curie temperatures from 700 °C (973 K) to 800 °C (1,070 K)

– Expensive and subject to price fluctuations (cobalt is market price sensitive)

Production

The reduction/melt method and reduction/diffusion method are used to manufacture samarium–cobalt magnets. The reduction/melt method will be described since it is used for both SmCo5 and Sm2Co17 production. The raw materials are melted in an induction furnace filled with argon gas. The mixture is cast into a mold and cooled with water to form an ingot. The ingot is pulverized and the particles are further milled to further reduce the particle size. The resulting powder is pressed in a die of desired shape, in a magnetic field to orient the magnetic field of the particles. Sintering is applied at a temperature of 1100˚C–1250˚C, followed by solution treatment at 1100˚C–1200˚C and tempering is finally performed on the magnet at about 700˚C–900˚C.[citation needed] It then is ground and further magnetized to increase its magnetic properties. The finished product is tested, inspected and packed

Applications

The properties of SmCo5 magnets make them ideal for use in many different applications. These magnets can be found in various industries, including automotive, aerospace, electronics, medical, and more. In the automotive industry, for example, SmCo5 magnets are commonly used in the electric motors of hybrid and electric vehicles. In the medical industry, on the other hand, these magnets are used in MRI machines and other medical devices.

In conclusion, SmCo5 magnets are an excellent choice for merchants looking to expand their product offerings. These magnets are versatile, high-performance, and suitable for use in various applications. Their physical characteristics and resistance to demagnetization and corrosion make them a reliable choice for many different industries. At our manufacturing facility, we ensure that our SmCo5 magnets are of the highest quality, allowing our customers to get the best performance out of their products.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

Physical and mechanical properties

| Comparison of physical properties of sintered neodymium and Sm-Co magnets | ||

| Property | Neodymium | Sm-Co |

| Remanence (T) | 1–1.3 | 0.82–1.16 |

| Coercivity (MA/m) | 0.875–1.99 | 0.493–1.59 |

| Relative permeability | 1.05 | 1.05 |

| Temperature coefficient of remanence (%/K) | −0.12 | −0.03 |

| Temperature coefficient of coercivity (%/K) | −0.55..–0.65 | −0.15..–0.30 |

| Curie temperature (°C) | 320 | 800 |

| Density (g/cm3) | 7.3–7.5 | 8.2–8.4 |

| CTE, magnetizing direction (1/K) | 5.2×10−6 | 5.2×10−6 |

| CTE, normal to magnetizing direction (1/K) | −0.8×10−6 | 11×10−6 |

| Flexural strength (N/mm2) | 250 | 150 |

| Compressive strength (N/mm2) | 1100 | 800 |

| Tensile strength (N/mm2) | 75 | 35 |

| Vickers hardness (HV) | 550–650 | 500–650 |

| Electrical resistivity (Ω·cm) | (110–170)×10−6 | 86×10−6 |

We can provide

1. Best package: Any requirement for package can be satisfied.

2. Fast reply: All your inquiry will be replied within 24 hours.

3. Reasonable price: we are direct manufacturer and able to offer better price.

4. Good quality: we are experienced in quality control.

5. Full-way tracking the cargo for you before the goods arrive.

IN ORDER TO QUOTE YOU THE BEST PRICE, PLEASE PROVIDE US THE FOLLOWING INFORMATION.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

—————————————————————————————————————————————————————————————————————————-