Sm2Co17 Magnets

Sm2Co17 magnet is a type of rare-earth permanent magnet that is regarded as the second strongest magnet after NdFeB. It is made up of samarium (Sm), cobalt (Co), and a few other elements. It is important to note that Sm2Co17 magnet’s composition differs significantly from the standard SmCo5 magnet, making it much stronger and more durable.

Product Information

Sm2Co17 magnets(Sm2Co17) are mainly in proportion to the metals samarium, cobalt, copper, iron and zirconium. It has a (BH) maximum range of 20 to 32 and a maximum operating temperature of 350°C. Sm2Co17 has a very low temperature coefficient and good corrosion resistance. When working in a high temperature environment, the magnetic properties of samarium cobalt magnets are better than that of neodymium iron boron magnets. Therefore, samarium cobalt magnets are widely used in aerospace, defense, and sensors.

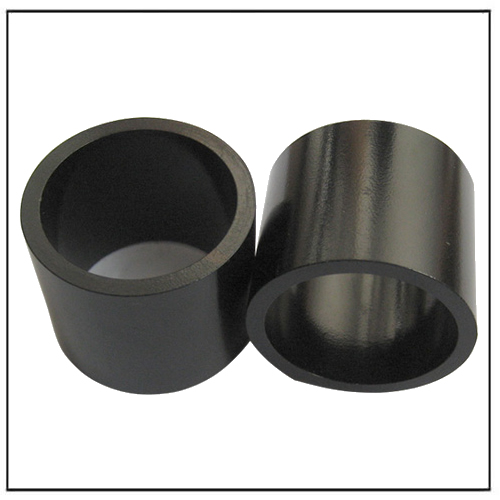

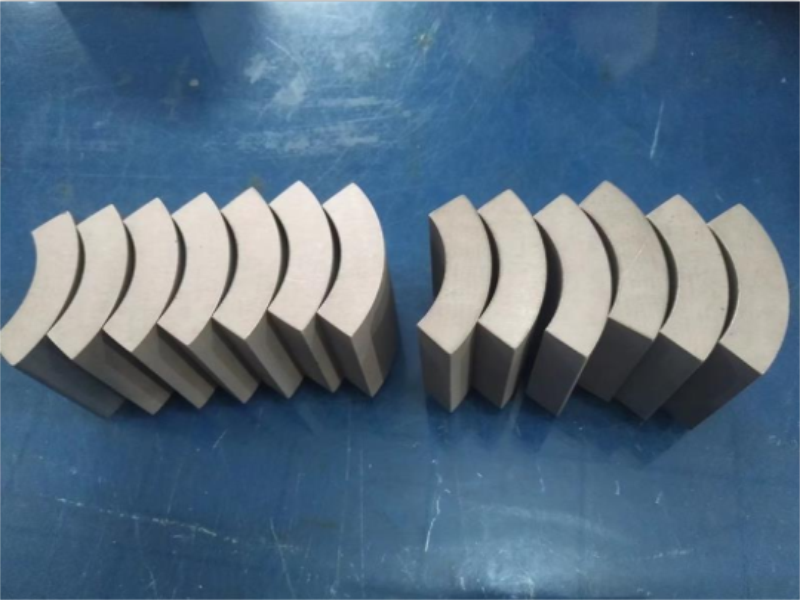

Due to the brittleness of the Sm2Co17 material, Sm2Co17 magnet is not suitable for discs or rings with complex shapes and thin thicknesses. Also due to this feature, some cosmetic defects may occur during production, inspection and magnetization. However, the magnetism will not be affected. They are generally similar in strength to neodymium magnets, but have higher temperature ratings and higher coercivity.

Attributes

-Extremely resistant to demagnetization

– Good temperature stability (maximum use temperatures between 250 °C (523 K) and 550 °C (823 K); Curie temperatures from 700 °C (973 K) to 800 °C (1,070 K)

– Expensive and subject to price fluctuations (cobalt is market price sensitive)

Production

The reduction/melt method and reduction/diffusion method are used to manufacture samarium–cobalt magnets. The reduction/melt method will be described since it is used for both SmCo5 and Sm2Co17 production. The raw materials are melted in an induction furnace filled with argon gas. The mixture is cast into a mold and cooled with water to form an ingot. The ingot is pulverized and the particles are further milled to further reduce the particle size. The resulting powder is pressed in a die of desired shape, in a magnetic field to orient the magnetic field of the particles. Sintering is applied at a temperature of 1100˚C–1250˚C, followed by solution treatment at 1100˚C–1200˚C and tempering is finally performed on the magnet at about 700˚C–900˚C.[citation needed] It then is ground and further magnetized to increase its magnetic properties. The finished product is tested, inspected and packed

Benefits and Applications

Sm2Co17 magnet is an ideal choice for various industrial applications where high-performance magnets are required. It has unique features that make it suitable for applications where other magnets fail to perform. Below are some of the benefits and applications of Sm2Co17 magnet.

1. High-Temperature Stability

Sm2Co17 magnet exhibits excellent magnetic properties at high temperatures compared to other magnets. It can withstand temperatures of up to 350°C without undergoing significant loss of magnetic properties. This makes it an ideal choice for applications that require high-temperature stability, such as electric motors, generators, and aerospace applications.

2. High Coercivity:

Sm2Co17 magnets have high coercivity, which means that they can withstand external demagnetizing forces. Thus, they are ideal for applications where magnets are subjected to high shock and vibration, such as missile guidance systems, medical equipment, and military hardware.

3. Higher Corrosion Resistance:

Compared to other rare-earth magnets, Sm2Co17 magnets have higher corrosion resistance properties owing to their Co content. They are well suited for underwater applications, such as marine motors, as well as medical equipment that requires cleaning with harsh chemicals.

4. High Energy Product:

Sm2Co17 magnets have a high energy product, which means that they can store and deliver a significant amount of magnetic energy per unit volume. This makes them the ideal choice for applications that require high-energy storage, such as hybrid cars, wind power generators, and elevators.

5. Consistent Magnetic Properties:

Sm2Co17 magnets have consistent magnetic properties over a wide range of temperatures and magnetic fields. This makes them the ideal choice for precision applications such as magnetic bearings, magnetic sensors, and scientific instruments.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality Sm2Co17 Magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

Physical and mechanical properties

| Comparison of physical properties of sintered neodymium and Sm-Co magnets | ||

| Property | Neodymium | Sm-Co |

| Remanence (T) | 1–1.3 | 0.82–1.16 |

| Coercivity (MA/m) | 0.875–1.99 | 0.493–1.59 |

| Relative permeability | 1.05 | 1.05 |

| Temperature coefficient of remanence (%/K) | −0.12 | −0.03 |

| Temperature coefficient of coercivity (%/K) | −0.55..–0.65 | −0.15..–0.30 |

| Curie temperature (°C) | 320 | 800 |

| Density (g/cm3) | 7.3–7.5 | 8.2–8.4 |

| CTE, magnetizing direction (1/K) | 5.2×10−6 | 5.2×10−6 |

| CTE, normal to magnetizing direction (1/K) | −0.8×10−6 | 11×10−6 |

| Flexural strength (N/mm2) | 250 | 150 |

| Compressive strength (N/mm2) | 1100 | 800 |

| Tensile strength (N/mm2) | 75 | 35 |

| Vickers hardness (HV) | 550–650 | 500–650 |

| Electrical resistivity (Ω·cm) | (110–170)×10−6 | 86×10−6 |

We can provide

1. Best package: Any requirement for package can be satisfied.

2. Fast reply: All your inquiry will be replied within 24 hours.

3. Reasonable price: we are direct manufacturer and able to offer better price.

4. Good quality: we are experienced in quality control.

5. Full-way tracking the cargo for you before the goods arrive.

IN ORDER TO QUOTE YOU THE BEST PRICE, PLEASE PROVIDE US THE FOLLOWING INFORMATION.

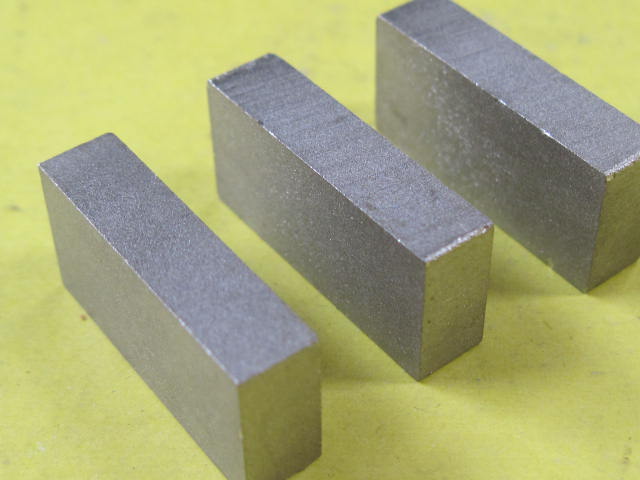

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

—————————————————————————————————————————————————————————————————————————-