Samarium Cobalt Magnets

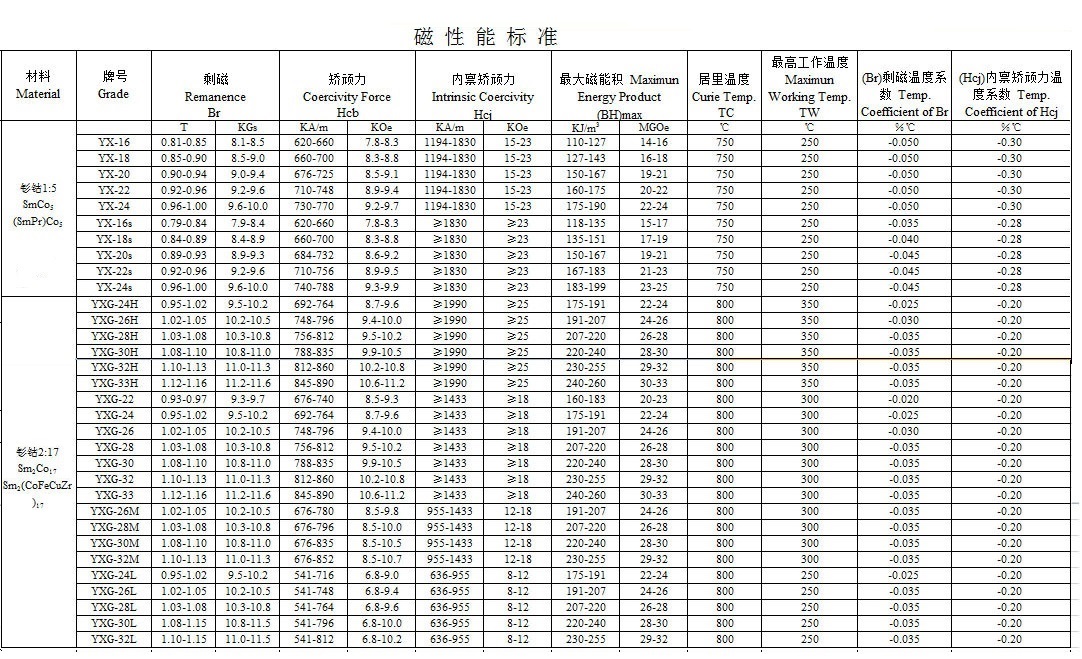

Samarium cobalt magnets currently have two main compositions: SmCo5 and Sm2Co17. They are made by smelting alloys of samarium, cobalt, and other rare earth metals in proportion, followed by crushing, pressing, and sintering to form a magnetic material. They possess high magnetic energy product, extremely low temperature coefficients, and can withstand temperatures up to 350°C. There is no temperature limitation for negative temperature coefficients. When operating at temperatures above 180°C, their temperature stability and chemical stability surpass that of neodymium iron boron permanent magnet materials.

Introduction of SmCo Magnet

SmCo(Samarium Cobalt) magnet is a kind of material made from rare earth metal samarium and cobalt, which features of high performance, low temperature coefficient, good temperature stability and strong corrosion resistance. When working above 180 degree centigrade, its maximum energy product BH and steady temperature are superior than NdFeB magnetic material. Due to its strong corrosion resistance, SmCo magnet need not to be coated since it is difficult to be eroded and oxidized.

SmCo magnet is widely used in space probe, national defense and military, microwave appliance, communication, medical equipments, motors, instruments, various magnetism spreading devices, sensor, magnetic processor, magnetic lifter and so on.

SmCo1:5 magnet is also named SmCo5, which is prorated with metallic samarium, cobalt and metallic praseodymium. The (BH) max range is from 16 to 25, maximum working temperature 250°C. The physical character and ductibility of SmCo5 is better than Sm2Co17, so SmCo5 is slightly easier to be machined with complex shapes and thin thickness of disc or ring, while Sm2Co17 is more brittle. Magnetization magnetic field of SmCo5 is lower compared with Sm2Co17. In general, SmCo5 can be magnetized saturated by 4000Gs magnetic field, however, magnetizing Sm2Co17 with high Hcj value need more than 6000Gs magnetic field. For some reasons, the price of SmCo5 is more expensive than Sm2Co17. According to different applications and using requirements, customer can choose SmCo5 or Sm2Co17 reasonably. .

SmCo2:17 magnet (Sm2Co17) is mainly prorated with metallic samarium, cobalt, Copper, iron and zirconium. The (BH) max range is from 20 to 32, maximum working temperature 350°C. Sm2Co17 bears extremely low temperature coefficient and preferably anti-causticity. When working in high-temperature environment, magnetic properties of SmCo magnet is better than NdFeB magnet. Thus, SmCo magnets are widely used in fields such as aeronautics and space, national defense and sensors. Because of great brittleness of Sm2Co17 materials, it is not suitable for complex shapes and disc or ring with thin thickness. Also due to this character, there may be some appearance defects such as small chips during production, inspection and magnetizing process. However, magnetic property will not be affected.

Attractive Features of SmCo Magnets:

Now let’s look at some of the key features that make SmCo magnets an attractive option for various industries.

1. High Magnetic Performance: SmCo magnets exhibit exceptional magnetic properties with a high energy product (BH)max. This makes them the ideal choice for applications where high magnetic performance is required.

2. Temperature Stability: SmCo magnets have excellent temperature stability and can maintain their magnetic properties even in high-temperature environments. With a maximum operating temperature of up to 300°C, they are ideal for use in high-temperature applications.

3. Corrosion Resistance: SmCo magnets are highly resistant to corrosion and can withstand exposure to a wide range of chemicals and harsh environments. This makes them ideal for use in industrial and marine applications.

4. Durability: SmCo magnets are known for their durability and long service life. They can withstand high levels of vibration, shock, and mechanical stress, making them ideal for use in automotive and aerospace applications.

5. Size and Shape Versatility: SmCo magnets can be customized into different sizes and shapes to meet the specific requirements of different applications. This versatility makes them the ideal choice for a broad range of industrial applications.

Applications of SmCo Magnets:

Now that we have understood the key features of SmCo magnets, let’s explore some of the applications where they are widely used:

1. Motors and Generators: SmCo magnets are extensively used in motors and generators to generate a strong magnetic field required for power generation.

2. Medical Equipment: SmCo magnets are used in medical equipment such as MRI machines, where a strong magnetic field is required for imaging purposes.

3. Aerospace: SmCo magnets are used in aerospace applications for their exceptional temperature stability and durability.

4. Renewable Energy: SmCo magnets are also used in renewable energy applications such as wind turbines, where a strong and reliable magnetic field is required to generate electricity.

5. Audio and Video Equipment: SmCo magnets are used in audio and video equipment for their exceptional magnetic properties that help in delivering high-quality output.

In conclusion, SmCo magnets are an excellent choice for a wide range of industrial applications. With their exceptional magnetic properties, temperature stability, and durability, they offer superior performance compared to other types of magnets. We, as a manufacturer, take great pride in our product quality and customer service. We ensure that each of our SmCo magnets is manufactured with the highest standards of quality and performance to meet the specific requirements of our customers. If you are looking for high-quality SmCo magnets at a competitive price, please do not hesitate to contact us!

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

Introduction

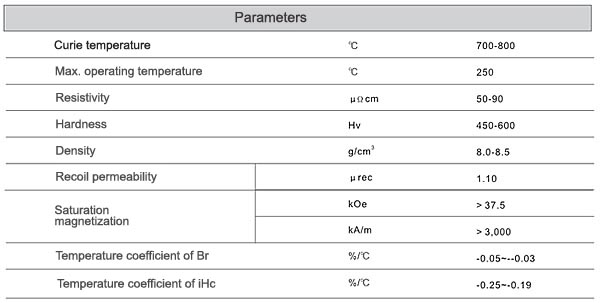

- Material: Sintered Samarium Cobalt (SmCo); Samarium cobalt magnets (SmCo) are divided into SmCo5 and Sm2Co17 based on their composition. They are made from samarium, cobalt, and other rare earth metals in proportion, melted into an alloy, and then crushed, pressed, and sintered to form a magnetic material. They possess high magnetic energy product, extremely low temperature coefficients, and can withstand temperatures up to 350°C. There is no temperature limitation for negative temperature coefficients. When operating at temperatures above 180°C, their maximum magnetic energy product, temperature stability, and chemical stability surpass that of neodymium iron boron permanent magnet materials. They exhibit strong corrosion resistance and oxidation resistance; hence, they are widely used in aerospace, national defense, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic lifters, etc. Samarium cobalt magnet shapes include discs, rings, squares, tiles, wafers, and special shapes can be customized according to drawings.

- Shape: Discs, rings, squares, tiles, special shapes;

- Size: Any variable size, can be customized according to customer requirements;

- Maximum operating temperature: ≤350°C;

- Product performance grades: YXG24-YXG32, YXG24H-YXG30H;

- Surface treatment: Surface treatment is usually not necessary as they do not rust, but nickel plating is possible;

- Packaging: Standard sea, land, or air transportation packaging, can be customized according to customer requirements for ease of handling and transportation without damaging the product;

- Delivery time: Generally 7-20 days, specific delivery time is subject to agreement between both parties based on quantity and process requirements.

Physical property

Magnetic properties

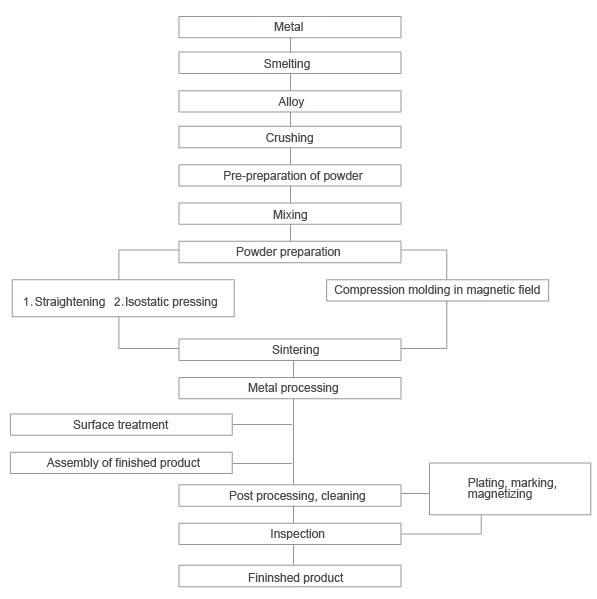

Flow chart

| Comparison of physical properties of sintered neodymium and Sm-Co magnets | ||

| Property | Neodymium | Sm-Co |

| Remanence (T) | 1–1.3 | 0.82–1.16 |

| Coercivity (MA/m) | 0.875–1.99 | 0.493–1.59 |

| Relative permeability | 1.05 | 1.05 |

| Temperature coefficient of remanence (%/K) | −0.12 | −0.03 |

| Temperature coefficient of coercivity (%/K) | −0.55..–0.65 | −0.15..–0.30 |

| Curie temperature (°C) | 320 | 800 |

| Density (g/cm3) | 7.3–7.5 | 8.2–8.4 |

| CTE, magnetizing direction (1/K) | 5.2×10−6 | 5.2×10−6 |

| CTE, normal to magnetizing direction (1/K) | −0.8×10−6 | 11×10−6 |

| Flexural strength (N/mm2) | 250 | 150 |

| Compressive strength (N/mm2) | 1100 | 800 |

| Tensile strength (N/mm2) | 75 | 35 |

| Vickers hardness (HV) | 550–650 | 500–650 |

| Electrical resistivity (Ω·cm) | (110–170)×10−6 | 86×10−6 |

We can provide

1. Best package: Any requirement for package can be satisfied.

2. Fast reply: All your inquiry will be replied within 24 hours.

3. Reasonable price: we are direct manufacturer and able to offer better price.

4. Good quality: we are experienced in quality control.

5. Full-way tracking the cargo for you before the goods arrive.

IN ORDER TO QUOTE YOU THE BEST PRICE, PLEASE PROVIDE US THE FOLLOWING INFORMATION.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

What are Samarium Cobalt (SmCo) magnets?

Samarium Cobalt magnets are a type of rare-earth magnet made from an alloy of samarium and cobalt. They are known for their high magnetic strength, excellent temperature stability, and resistance to corrosion. They come in two main varieties: SmCo_5 (1:5 series) and Sm_2Co_17 (2:17 series), indicating the ratio of samarium to cobalt.

How do SmCo magnets compare to Neodymium (NdFeB) magnets?

While both SmCo and NdFeB magnets are considered rare-earth magnets and possess high magnetic strengths, SmCo magnets excel in high-temperature environments and have superior corrosion resistance without the need for protective coatings. Neodymium magnets are generally stronger at room temperature and are more cost-effective but have lower temperature resistance and are more prone to corrosion.

What are the main applications of SmCo magnets?

SmCo magnets are used in various applications where high magnetic strength and temperature stability are required. Common uses include aerospace and defense systems, automotive sensors and motors, medical devices, and industrial applications such as magnetic couplings and high-temperature motors.

Can SmCo magnets work under high temperature?

Yes, SmCo magnets are particularly valued for their ability to maintain magnetic properties at high temperatures, up to 300°C (572°F) for some grades. This makes them suitable for applications exposed to high thermal environments.

Are SmCo magnets corrosion-resistant?

Yes, SmCo magnets have good corrosion resistance and do not typically require any protective coating, unlike neodymium magnets, which often need to be coated to prevent corrosion.

How strong are SmCo magnets?

SmCo magnets have high magnetic strength, though not as high as the strongest neodymium magnets. Their strength is sufficient for most applications where temperature stability and corrosion resistance are also important factors.

Are there any handling concerns with SmCo magnets?

Like other rare-earth magnets, SmCo magnets are brittle and can chip or break if mishandled. They should be handled with care, especially when large magnets are involved, as they can snap together with significant force.

How are SmCo magnets made?

The manufacturing process of SmCo magnets involves melting the raw materials, casting the alloy, milling it into a powder, pressing the powder in a magnetic field, sintering, and then machining the magnet to its final dimensions. The magnets are then magnetized to achieve their full magnetic potential.

Do SmCo magnets need a protective coating?

Generally, SmCo magnets do not require a protective coating due to their inherent corrosion resistance. However, for specific applications or environments, a coating might be applied for additional protection or for aesthetic reasons.

How do I choose between a SmCo and a Neodymium magnet for my application?

The choice between SmCo and neodymium magnets depends on several factors, including the required magnetic strength, temperature conditions, exposure to corrosive elements, and budget constraints. For high-temperature applications or environments where corrosion resistance is crucial without coatings, SmCo magnets are the preferred choice. For applications requiring the highest magnetic strength at room temperature and where cost is a significant factor, neodymium magnets are more suitable.

—————————————————————————————————————————————————————————————————————————-