NdFeb Disc Magnets

NdFeB disc magnets are used in a huge variety of applications, from use in Hall Effect Sensors and Reed Switches, through to clamping applications, office use, generator use, educational, etc. We can produce the NdFeB disc magnets in different sizes, different grades (strengths and temperature ratings), different coatings/finishes and in diametric magnetization as part of our custom magnet service.

Product Description

NdFeB disc magnets are used in a huge variety of applications, from use in Hall Effect Sensors and Reed Switches, through to clamping applications, office use, generator use, educational, etc.

We can produce the NdFeB disc magnets in different sizes, different grades (strengths and temperature ratings), different coatings/finishes and in diametric magnetization as part of our custom magnet service.

Super strong Rare-Earth magnets – they are hard to break apart once they get stuck with each other. Can also be used to extend protected lithium batteries with recessed contact points. Perfect for sticking notes on fridge doors.

It suitable for DIY projects, such as whiteboard fixing, adsorption of various steel parts,ixing tissue box on the roof, etc.

We are among the reputed organizations, deeply engaged in offering an optimum quality range of NdFeB disc magnets. You will receive a positive and consistent customer service experience every time you contact us.

Features of NdFeb Disc Magnets

Magnetic Strength: NdFeb Disc Magnets are known to have high coercivity and high magnetic energy levels. Due to the high energy levels, the magnets can attract or repel another magnet from a distance. The coercivity of the NdFeb Disc Magnets determines the magnetic strength, which means that a higher coercivity implies a stronger magnet. These magnets have the most potent magnetic pull force of any type of magnet available today.

Size Range: NdFeb Disc Magnets come in an extensive range of sizes, allowing merchants to choose the perfect magnet for their application. The disc shape of these magnets ensures that the size ranges from small to large, making it easy to apply them in various places.

Temperature Resistance: Unlike other magnets with moderate-to-low temperature resistance, NdFeb Disc Magnets have high-temperature resistance. The magnets can handle temperatures of up to 200°C without losing their magnetic strength. This feature makes NdFeb Disc Magnets ideal for use in high-temperature environments.

Durability: NdFeb Disc Magnets are long-lasting, and they can retain their magnetism for over 10 years. They are resistant to corrosion and can withstand harsh environments such as exposure to extreme temperatures, moisture, and chemicals. The magnets also have high resistance to demagnetization, which makes them suitable for heavy-duty applications.

Applications of NdFeb Disc Magnets

NdFeb Disc Magnets have a wide range of applications in various industries thanks to their high-performance features. These magnets can be used in:

1. Motors and Generators: NdFeb Disc Magnets are used in motors and generators as they provide a high level of magnetic energy that creates torque and speed. They are used in hard drives, speakers, and quartz watches due to their high magnetic strength.

2. Health Care: NdFeb Disc Magnets are used in the health sector to create medical devices and imaging technology. For example, they are used in MRI machines and pacemakers.

3. Defence: NdFeb Disc Magnets are used in military applications such as missile guidance systems, stealth technology, and radar systems.

4. Automotive Industry: NdFeb Disc Magnets are used in the automotive industry for electric cars, windscreen wipers, and power steering systems.

5. Toys and Games: NdFeb Disc Magnets are used in toy applications such as building blocks, puzzles, and educational learning aids.

In conclusion, NdFeb Disc Magnets are an exceptional choice for various applications. Our company offers the best quality of NdFeb Disc Magnets at an affordable price. Our magnets have high magnetic strength, are durable, and can withstand harsh environments. Their versatility makes them a perfect choice for various industries such as the automotive, health, and military industries. Our NdFeb Disc Magnets are available in a wide range of sizes, and we can customize our products according to the specifications of our customers. We are committed to providing the best services and products to our clients, and we take pride in our timely shipping and excellent customer service. We welcome customers from all over the world to partner with us and experience the benefits of our NdFeb Disc Magnets.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

| Material | Neodymium-Iron-Boron | |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| N35M- N50M | 100°C (212°F) | |

| N35H-N48H | 120°C (248°F) | |

| N35SH-N45SH | 150°C (302°F) | |

| N28UH-N40UH | 180°C (356°F) | |

| N28EH-N38EH | 200°C (392°F) | |

| N28AH-N35AH | 220°C (428°F) | |

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.Customized shapes for Sintered Neodymium Strong Magnets are available. | |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Phosphating, Chemical, PTFE, ParyleneEverlube, Passivation and more. | |

| Magnetization Direction | a. Thickness Magnetizedb. Axially Magnetizedc. Diametrally Magnetizedd. Multi-poles magnetizede. Radial Magnetizedf. Customized specific requirements magnetized | |

| Delivery Time | The lead time around 10-25days | |

| Payment Terms | L/C,T/T,Paypal, ESCROW, Western Union | |

Surface Treatment of NdFeB magnet

NdFeB magnets are susceptible to corrosion, so it is necessary to give surface treatment Currently, the surface treatments mainly includes chemical plating, conversion coating and coating. In most cases, NdFeB magnet surface are treated with NiCuNi (Nickel-Copper-Nickel) plating, Zinc plating and Epoxy coating. For special requirements, passivation and phosphatization are also adopted.

| Plating Instructions | ||||

| Type | Coating | Thickness | Color | SST(Hours) |

| Nickel | Ni+Cu+Ni | 10~20 μm | Bright Silver | 24~72 |

| Black Nickel | Ni+Cu+Black Ni | 10~20 μπ | Bright Black | 48~96 |

| Cr3+Zinc | Zinc | 5~8μm | Blue white | 16~48 |

| Color Zinc | 5~8μm | Colorful | 36~72 | |

| Sn | Ni+Cu+Ni+Sn | 10~25μm | Silver | 36~72 |

| Au | Ni+Cu+Ni+Au | 10~20 μm | Gold | 12 |

| Ag | Ni+Cu+Ni+Ag | 10~20μm | Silver | 12 |

| Epoxy | Exopy | 10~20μm | Black/Grey | 48 |

| Ni+Cu+Epoxy | 15~30μm | 72~108 | ||

| Zn+Epoxy | 15~25μm | 72~108 | ||

| Passivation | //// | 1~3μm | Dark Grey | temporary protection |

| Phosphatization | //// | 1~3μm | Dark Grey | temporary protection |

In order to quote you the best price, please provide us the following information.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

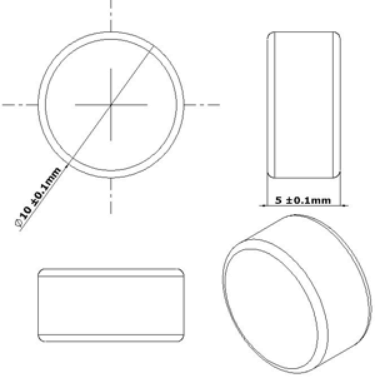

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

What are neodymium disc magnets?

Neodymium disc magnets are strong permanent magnets made from an alloy of neodymium, iron, and boron. They have a flat, circular shape and are part of the rare-earth magnet family, known for their exceptional magnetic strength relative to their size.

How strong are neodymium disc magnets?

The strength of neodymium disc magnets depends on their size, shape, and grade. They are among the strongest types of permanent magnets available, capable of holding materials many times their own weight. Magnet strength is typically indicated by a grade number, with higher numbers representing stronger magnets.

What are the common uses of neodymium disc magnets?

Neodymium disc magnets are used in a wide variety of applications, including in electronics (like headphones, speakers, and hard drives), in medical devices (such as MRI machines), in industrial settings (for motors, generators, and magnetic separation), and in personal or home uses (like jewelry clasps and door catches).

Can neodymium disc magnets be used outdoors?

Yes, but their suitability for outdoor use depends on the type of coating they have. Coatings like nickel, zinc, or epoxy help protect the magnets from corrosion. Epoxy coatings offer the best protection against moisture and are recommended for outdoor use.

How do you handle neodymium disc magnets safely?

To handle neodymium disc magnets safely, use caution to prevent them from snapping together and potentially causing injuries. Always keep them away from children and pets to avoid swallowing hazards, and maintain a safe distance from electronic devices and magnetic storage media to prevent damage.

Do neodymium disc magnets lose their magnetism over time?

Under normal conditions, neodymium disc magnets maintain their magnetism for decades. However, they can lose their magnetism if exposed to high temperatures, strong external magnetic fields, or if they are physically damaged.

Can neodymium disc magnets affect electronic devices?

Yes, the strong magnetic fields generated by neodymium disc magnets can damage electronic devices and magnetic storage media. It’s important to keep magnets at a safe distance from such items.

Are neodymium disc magnets coated?

Neodymium disc magnets are typically coated to prevent corrosion. Common coatings include nickel, zinc, and epoxy. The coating protects the magnet from moisture and other environmental factors that could lead to corrosion.

How do I choose the right neodymium disc magnet for my project?

Consider the weight of the object you need to hold, the environment in which the magnet will be used (especially if it’s outdoors or in humid conditions), and the space available for placing the magnet. The magnet’s grade (which indicates its strength) and its coating (for corrosion resistance) should be appropriate for your application.

How are neodymium disc magnets manufactured?

The manufacturing process includes melting the raw materials (neodymium, iron, and boron), casting the alloy, pulverizing it into a fine powder, pressing the powder in a magnetic field to align the particles, sintering the compacted alloy, and then machining it into the disc shape. Finally, the magnets are coated to prevent corrosion.

—————————————————————————————————————————————————————————————————————————-