NdFeb Arc Magnets

Neodymium arc magnets are a type of permanent magnet made from an alloy of neodymium, iron, and boron (NdFeB). They are shaped in segments of a circle, resembling arcs, and are specifically designed to fit into circular or cylindrical assemblies. These magnets are part of the rare-earth magnet family, known for their exceptional strength and magnetic properties compared to other types of permanent magnets.

Product Description

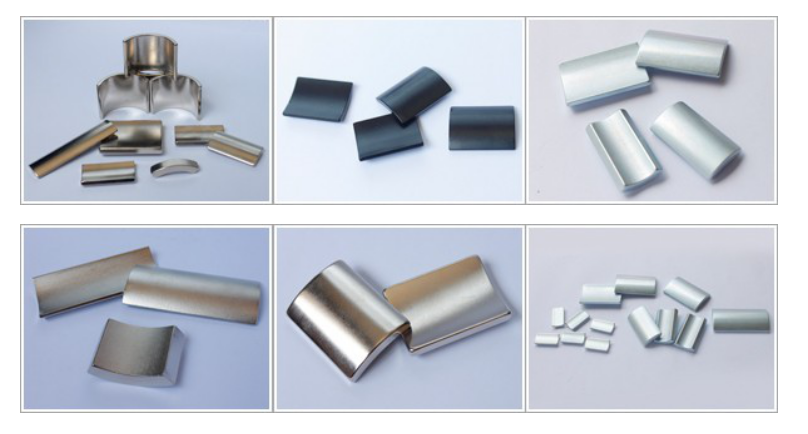

NdFeb arc magnets are one of the basic shapes of neodymium magnets, also known as NdFeB segmented magnets. Magnets are available in high Hcj materials to match special motor applications. Its torque performance and grounding consistency meet high precision and concentricity requirements.

Features

NdFeb arc magnets have high magnetic energy product and coercivity, and the motors made with it are smaller, lighter and thinner. Its magnetic performance is good, the magnetic energy product is three times that of anisotropic ferrite. And the intrinsic coercivity is high, the magnetic performance is stable in batch production, and the consistency is good. It has high precision, and can meet the precision requirements in one molding without excessive post-processing. It is lightweight and inexpensive, and is a relatively cost-effective magnet material.

The following are some of the standout features and benefits of our NdFeb arc magnets:

1. Strong Magnetic Force

Our NdFeb arc magnets are much stronger than conventional magnets, such as ferrite magnets or alnico magnets. In fact, our magnets are among the strongest commercially available magnets, with a maximum energy product of up to 52MGOe. This high magnetic force is made possible by the magnet’s unique crystal structure, which enables it to produce a strong magnetic field, even with small sizes. As a result, our NdFeb arc magnets are ideal for applications that require high magnetic intensity, such as strong electric motors, magnetic couplings, and other precision equipment.

2. Wide Range of Shapes and Sizes

We offer NdFeb arc magnets in a comprehensive variety of sizes, shapes, and grades to meet our customers’ diverse needs. These include segment magnets, block magnets, ring magnets, fan-shaped magnets, custom-shaped magnets, and more, with various dimensions and angles. We can also produce magnets in different grades, depending on the specific application for which they will be used. Whatever your requirements may be, we have a magnet that suits your needs.

3. Excellent Resistance to Demagnetization and Corrosion

Our NdFeb arc magnets are highly resistant to demagnetization and corrosion, thanks to their unique properties. They are also very stable under normal operating temperatures, making them well-suited for use in harsh conditions. Our magnets retain most of their initial magnetization even under extreme temperature or field conditions, ensuring they can withstand heavy use and last for longer periods of time. They also have excellent corrosion resistance and can be used in a variety of applications, including medical equipment, electronic appliances, and automotive manufacturing.

4. Cost-effective

Despite their exceptional strength and performance, our NdFeb arc magnets are cost-effective compared to other high-performance magnets. With our advanced manufacturing technology and industry experience, we can create NdFeb arc magnets that are both efficient and affordable. We are confident that we can supply high-quality magnets at a competitive price.

In summary, our NdFeb arc magnets are:

1. Highly powerful and efficient: Due to their high magnetic force, our magnets are ideal for a wide range of applications in numerous industries.

2. Available in a range of shapes and sizes: We offer an extensive variety of sizes, shapes, and grades to cater to our customers’ specific needs, making it easier to find the ideal magnet that meets your requirements.

3. Resistant to demagnetization and corrosion: Our magnets are incredibly durable and can withstand harsh environmental conditions and high-use scenarios, retaining their original magnetization and retaining their efficiency for longer.

4. Cost-effective: Despite their enhanced capabilities, these magnets are priced competitively, making them a cost-friendly option for many clients.

在创世纪新征程,我们致力于为客户提供最好的钕铁硼弧形磁铁。凭借我们的磁铁的创新设计、卓越的磁性和广泛的应用,我们相信我们拥有当今市场上的领先产品之一。我们邀请您联系我们并索取报价,以详细了解我们如何帮助您释放您的磁性潜力。

Application

钕铁硼弧形磁铁广泛应用于直流电机、交流电机、伺服电机、同步电机、驱动电机、调速电机等电机。许多电机制造商需要高温钕磁铁,例如N38SH磁铁、N35EH、N35UH磁铁等。

NdFeb arc magnets, made from a powerful, permanent magnet material based on neodymium, iron, and boron, are revolutionizing modern industry. They are used in wide-ranging applications including electric motors, generators, magnetic separation equipment, health therapy instruments, and more.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

| Material | Neodymium-Iron-Boron | |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| N35M- N50M | 100°C (212°F) | |

| N35H-N48H | 120°C (248°F) | |

| N35SH-N45SH | 150°C (302°F) | |

| N28UH-N40UH | 180°C (356°F) | |

| N28EH-N38EH | 200°C (392°F) | |

| N28AH-N35AH | 220°C (428°F) | |

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.Customized shapes for Sintered Neodymium Strong Magnets are available. | |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Phosphating, Chemical, PTFE, ParyleneEverlube, Passivation and more. | |

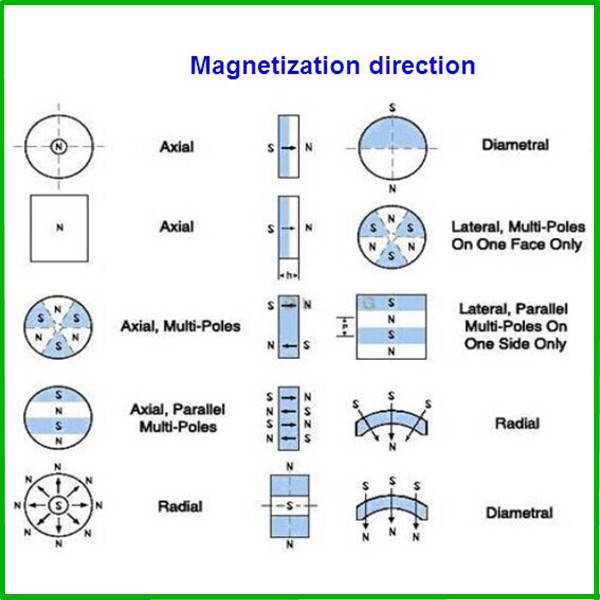

| Magnetization Direction | a. Thickness Magnetizedb. Axially Magnetizedc. Diametrally Magnetizedd. Multi-poles magnetizede. Radial Magnetizedf. Customized specific requirements magnetized | |

| Delivery Time | The lead time around 7-25days | |

| Payment Terms | T/T,L/C,XTrasfer | |

Surface Treatment of NdFeB magnet

NdFeB magnets are susceptible to corrosion, so it is necessary to give surface treatment Currently, the surface treatments mainly includes chemical plating, conversion coating and coating. In most cases, NdFeB magnet surface are treated with NiCuNi (Nickel-Copper-Nickel) plating, Zinc plating and Epoxy coating. For special requirements, passivation and phosphatization are also adopted.

| Plating Instructions | ||||

| Type | Coating | Thickness | Color | SST(Hours) |

| Nickel | Ni+Cu+Ni | 10~20 μm | Bright Silver | 24~72 |

| Black Nickel | Ni+Cu+Black Ni | 10~20 μπ | Bright Black | 48~96 |

| Cr3+Zinc | Zinc | 5~8μm | Blue white | 16~48 |

| Color Zinc | 5~8μm | Colorful | 36~72 | |

| Sn | Ni+Cu+Ni+Sn | 10~25μm | Silver | 36~72 |

| Au | Ni+Cu+Ni+Au | 10~20 μm | Gold | 12 |

| Ag | Ni+Cu+Ni+Ag | 10~20μm | Silver | 12 |

| Epoxy | Exopy | 10~20μm | Black/Grey | 48 |

| Ni+Cu+Epoxy | 15~30μm | 72~108 | ||

| Zn+Epoxy | 15~25μm | 72~108 | ||

| Passivation | //// | 1~3μm | Dark Grey | temporary protection |

| Phosphatization | //// | 1~3μm | Dark Grey | temporary protection |

In order to quote you the best price, please provide us the following information.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

What are neodymium arc magnets?

Neodymium arc magnets are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron, shaped in the form of an arc or segment. These magnets are designed to fit the round shape of motors and generators, providing a powerful magnetic field in a specific direction.

How do neodymium arc magnets differ from other neodymium magnets?

The main difference lies in their shape. While neodymium magnets can come in various forms, such as discs, blocks, or cubes, arc magnets are specifically cut into arc shapes to fit circular assemblies. This shape allows them to generate a directional magnetic field around the circumference of a circle, making them ideal for rotational applications.

What are the common uses for neodymium arc magnets?

Neodymium arc magnets are commonly used in high-performance motors, generators, and turbines. They are also found in electric vehicles, wind turbines, hard disk drives, and in various types of loudspeakers and dynamic microphones due to their ability to produce a strong magnetic field in a specific direction.

Can neodymium arc magnets be customized?

Yes, neodymium arc magnets can be customized in terms of size, angle, grade, and magnetic orientation to meet specific requirements. Customization is essential for them to fit precisely in the devices they are designed for, such as specific motor or generator models.

How strong are neodymium arc magnets?

Neodymium arc magnets are among the strongest types of magnets available, capable of generating significant magnetic force. The strength of an arc magnet depends on its grade, size, and the design of the magnetic circuit in which it is used.

Are neodymium arc magnets coated?

Like other neodymium magnets, arc magnets are typically coated to prevent corrosion. The coatings can include nickel, copper, zinc, or epoxy, which protect the magnet from moisture and chemical exposure.

Do neodymium arc magnets have a specific magnetic orientation?

Yes, neodymium arc magnets are manufactured with a specific magnetic orientation that is aligned with the arc’s geometry. This orientation is crucial for their use in motors and generators, where the magnetic field needs to interact precisely with the device’s other components.

How should neodymium arc magnets be handled?

Handling neodymium arc magnets requires caution due to their strong magnetic force. Protective gloves should be worn to prevent injuries, and the magnets should be kept at a safe distance from electronic devices and magnetic storage media to avoid damage.

Can neodymium arc magnets lose their magnetism?

Neodymium arc magnets can lose their magnetism if exposed to high temperatures, strong demagnetizing magnetic fields, or if they are physically damaged. However, under normal operating conditions, they can maintain their magnetism for decades.

How are neodymium arc magnets manufactured?

The manufacturing process for neodymium arc magnets involves melting the raw materials (neodymium, iron, and boron), casting the alloy into ingots, pulverizing the ingots into a fine powder, pressing the powder in a magnetic field to align the particles, sintering to fuse the particles, and then cutting the magnets into the desired arc shape before coating them for protection.

—————————————————————————————————————————————————————————————————————————-