NdFeB Adhesive Backed Magnets

Neodymium magnets with adhesive backing are ideal for a wide range of applications, including door and cabinet latches, packaging, box closure, and folder and notebox clasps, purses, jewelrey, and more.All adhesive-backed Neodymium magnets provide high bonding strength to most surfaces, including many low surface energy plastics such as polypropylene and powder coated paints.

Product Information

NdFeb adhesive backed magnets have practical size limitations. This is because the magnetic pull provided by the larger magnet will exceed the force of the adhesive to hold the magnet in place, and the force required to remove the magnet from another magnet or ferromagnetic material will exceed the strength of the bond, so the adhesive The strip will fail and tear off. We can supply high quality 3M adhesive backing. Simply peel off the protective cover from the adhesive and press into place to bond.

The NdFeb adhesive backed magnets are nickel-copper-nickel plated to protect them from corrosion, and regular magnetization through thickness. The most commonly used adhesive for this product is 3M 467 adhesive, but if you really need any other adhesive, such as foam adhesive, you can use it as well. Also, we offer different packaging methods for this product.

In applications such as using closed magnets to make folders and books, the NdFeb adhesive backed magnets may be glued to the material on the folder or book cover, and then the material they are glued to is folded over (effectively hiding the magnets from view), So that the magnets are clamped together, but with the adhesive side up (despite the layer of material between the adhesive layer and the magnets). This design hides the magnets, allowing the magnets to work (perhaps with less clamping force due to the greater distance between the magnets) and to clamp and prevent damage to the adhesive strip.

NdFeb adhesive-backed magnets are a must-have for any merchant. These magnets are manufactured in China and exported to countries outside of China, where they are sold to wholesalers and retailers. The magnets are made of a rare earth magnet known as neodymium iron boron (NdFeB), which is one of the strongest and most powerful magnets available in the market. The adhesive backing ensures that the magnets can be easily attached to any surface, making them versatile and ideal for a wide range of applications.

Features of NdFeb Adhesive Backed Magnets

1. High magnetic strength: The magnets are made of a rare earth magnet, which means that they have high magnetic strength compared to most other magnets in the market. This makes them perfect for a wide range of applications, including holding, attaching, and lifting objects.

2. Adhesive backing: The magnets come with a strong adhesive backing, which makes them easy to attach to any surface. The adhesive ensures that the magnets stay firmly attached to the surface, even when subjected to high pressure.

3. Versatility: The magnets can be used in a wide range of applications, including in the automotive industry, electronics industry, manufacturing, and packaging industry. They can be used to hold, attach or lift items in these industries, making them a must-have for any merchant dealing with these industries.

4. Durability: The magnets are made of high-quality materials that ensure they are durable and long-lasting. They can withstand harsh environments and extreme temperatures, making them perfect for outdoor use.

5. Cost-effective: The magnets are affordable, making them accessible to many customers. They are a cost-effective way of solving many industrial problems as they save time and money in the long run.

Applications of NdFeb Adhesive Backed Magnets

The versatility of NdFeb Adhesive Backed Magnets makes them useful in a wide range of applications. Below are some of the most common applications of these magnets:

1. Automotive industry: The magnets can be used to hold parts in place during assembly, repair, and maintenance of vehicles. They are also used to secure covers and doors of vehicles.

2. Electronics industry: The magnets are ideal for holding objects in place during the manufacture of electronic devices. They are also used in the assembly and repair of electronic devices.

3. Manufacturing: The magnets are used to hold objects in place during the manufacturing process. They are also used to secure objects during transportation and storage.

4. Packaging industry: The magnets are used to secure packages during storage and transportation. Moreover, they are also used to hold products in place during the packaging process.

NdFeb Adhesive Backed Magnets are a must-have for any merchant dealing with the automotive, electronics, manufacturing, and packaging industries. They are made of high-quality materials that ensure they are durable and long-lasting. The magnets have high magnetic strength and come with a strong adhesive backing, which makes them easy to attach to any surface. Their versatility makes them useful in a wide range of applications, making them a cost-effective solution for many industrial problems. The magnets are affordable, making them accessible to many customers. As a manufacturer located in China, we recommend that you add NdFeb Adhesive Backed Magnets to your product line to give your customers a reliable and cost-effective solution to their industrial problems.

NdFeb adhesive backed magnetss can also be used in small DIY packaging as well as industrial bulk packaging in the printing and display industry. They are ideal for invitation cards, envelopes, folders, jewelry boxes, jewelry boxes, music boxes, refrigerator magnets, and more. Just peel off each paired magnet and stick it in the desired area, and you’ve got a closed card, envelope, folder, and more.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

| Material | Neodymium-Iron-Boron | |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| N35M- N50M | 100°C (212°F) | |

| N35H-N48H | 120°C (248°F) | |

| N35SH-N45SH | 150°C (302°F) | |

| N28UH-N40UH | 180°C (356°F) | |

| N28EH-N38EH | 200°C (392°F) | |

| N28AH-N35AH | 220°C (428°F) | |

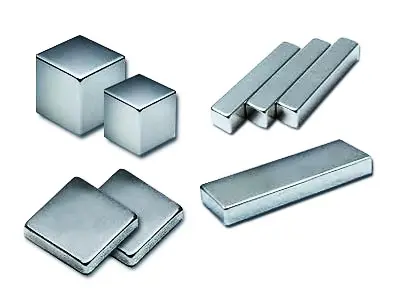

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.Customized shapes for Sintered Neodymium Strong Magnets are available. | |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Phosphating, Chemical, PTFE, ParyleneEverlube, Passivation and more. | |

| Magnetization Direction | a. Thickness Magnetizedb. Axially Magnetizedc. Diametrally Magnetizedd. Multi-poles magnetizede. Radial Magnetizedf. Customized specific requirements magnetized | |

| Delivery Time | The lead time around 10-25days | |

| Payment Terms | L/C,T/T,Paypal, ESCROW, Western Union | |

Surface Treatment of NdFeB magnet

NdFeB magnets are susceptible to corrosion, so it is necessary to give surface treatment Currently, the surface treatments mainly includes chemical plating, conversion coating and coating. In most cases, NdFeB magnet surface are treated with NiCuNi (Nickel-Copper-Nickel) plating, Zinc plating and Epoxy coating. For special requirements, passivation and phosphatization are also adopted.

| Plating Instructions | ||||

| Type | Coating | Thickness | Color | SST(Hours) |

| Nickel | Ni+Cu+Ni | 10~20 μm | Bright Silver | 24~72 |

| Black Nickel | Ni+Cu+Black Ni | 10~20 μπ | Bright Black | 48~96 |

| Cr3+Zinc | Zinc | 5~8μm | Blue white | 16~48 |

| Color Zinc | 5~8μm | Colorful | 36~72 | |

| Sn | Ni+Cu+Ni+Sn | 10~25μm | Silver | 36~72 |

| Au | Ni+Cu+Ni+Au | 10~20 μm | Gold | 12 |

| Ag | Ni+Cu+Ni+Ag | 10~20μm | Silver | 12 |

| Epoxy | Exopy | 10~20μm | Black/Grey | 48 |

| Ni+Cu+Epoxy | 15~30μm | 72~108 | ||

| Zn+Epoxy | 15~25μm | 72~108 | ||

| Passivation | //// | 1~3μm | Dark Grey | temporary protection |

| Phosphatization | //// | 1~3μm | Dark Grey | temporary protection |

In order to quote you the best price, please provide us the following information.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

Q1: How are NdFeB magnets utilized in the automotive industry?

A1: NdFeB magnets play a crucial role in automotive applications, particularly in electric vehicles (EVs) and hybrid vehicles. They are used in electric motors and generators to provide the strong magnetic fields necessary for efficient power generation and propulsion. NdFeB magnets also contribute to the miniaturization and lightweighting of automotive components, helping to improve fuel efficiency and performance.

Q2: What role do NdFeB magnets play in renewable energy generation?

A2: In the renewable energy sector, NdFeB magnets are essential components in wind turbines and electric generators. These magnets are used in the permanent magnet generators (PMGs) of wind turbines to convert kinetic energy from the wind into electrical energy. Their high magnetic strength

and stability enable efficient power generation, making wind energy a viable and sustainable source of electricity.

Q3: How are NdFeB magnets utilized in electronics and consumer devices?

A3: NdFeB magnets are commonly used in a wide range of electronic devices and consumer products. They can be found in speakers, headphones, hard disk drives, and magnetic sensors, where their strong magnetic fields and compact size are essential for achieving high performance and reliability. Additionally, NdFeB magnets are used in various home appliances, such as refrigerators, washing machines, and vacuum cleaners, enhancing their functionality and efficiency.

Q4: What applications do NdFeB magnets have in the medical industry?

A4: In the medical field, NdFeB magnets are utilized in magnetic resonance imaging (MRI) machines and medical devices. They play a critical role in generating the magnetic fields required for imaging and diagnostic purposes in MRI machines. NdFeB magnets are also used in magnetic therapy devices and medical sensors, where their strong magnetic fields can provide therapeutic benefits or precise measurements for medical diagnostics and treatments.

Q5: How do NdFeB magnets contribute to industrial manufacturing processes?

A5: NdFeB magnets are widely used in industrial manufacturing processes for various applications. They are employed in magnetic separators to remove ferrous contaminants from materials in industries such as mining, recycling, and food processing, ensuring product quality and safety. Additionally, NdFeB magnets are used in industrial automation systems, magnetic couplings, and lifting equipment, where their strong magnetic properties enhance efficiency, reliability, and productivity in manufacturing operations.

—————————————————————————————————————————————————————————————————————————-