AlNiCo Magnets

Alnico is one of the earliest developed permanent magnet materials, consisting of aluminum, nickel, cobalt, iron, and other trace metal elements. It is an alloy that can be produced through either sintering or casting processes. The shapes of the products are mostly round and square. Different sizes and shapes can be produced using the casting process; compared to casting, sintered products are limited to smaller sizes, with better dimensional tolerances in the produced blanks but slightly lower magnetic properties. However, they have better machinability. Among permanent magnetic materials, cast Alnico magnets have the lowest reversible temperature coefficient, with an operating temperature that can exceed 600 degrees Celsius. Alnico permanent magnetic products are widely used in various instruments and other application fields.

Description

Alnico magnets are alloys made of aluminum, nickel, cobalt, copper, iron, and other materials. They are divided into two types: cast Alnico and sintered Alnico, depending on the processing technology. They are widely used in aerospace, aviation, military, internal magnetic voltage and current meters, electronic energy meters, multimeters, flow meters, etc. They are also used in various magnetic sensors, polarized relays, temperature and pressure controllers, mobile phone buzzers, hearing aids, receivers, microspeakers, car ignition starters, car and motorcycle odometers, and more.

Cast Alnico magnets have higher magnetic properties and can be produced in various sizes and shapes. Sintered Alnico has a simpler process and can be directly pressed into the desired size. The advantages of Alnico magnets include low temperature coefficients, resulting in minimal changes in magnetic properties due to temperature variations. They can operate at temperatures up to 400 degrees Celsius and have strong resistance to moisture, oxidation, and good operational stability. Alnico magnets have strong corrosion resistance and do not require surface electroplating treatment.

Sintered Alnico uses the same materials as cast Alnico but is produced using powder metallurgy methods. It is suitable for producing products with complex, light, thin, and small shapes and is widely used in instruments, communication devices, magnetic switches, and various sensors.

Alnico magnets are ideal for corrosive and high heat applications up to 930°F (500°C).

Alnico magnets are commonly used for various types of sensors.

The Alnico Horseshoe Magnet has two magnetic poles close together. Ideal for school experiments and it makes a great gift. Includes a keeper to help retain magnetic power.

AlNiCo Magnets Properties and Characteristics

- High Magnetic Strength: Alnico magnets are known for their strong magnetic fields, although they are generally surpassed by rare earth magnets such as neodymium.

- High Temperature Resistance: One of the key advantages of Alnico magnets is their excellent ability to maintain magnetic strength at high temperatures, up to about 540°C (1000°F). This makes them suitable for applications where high temperature resistance is crucial.

- Corrosion Resistance: They exhibit good resistance to corrosion and typically do not require additional surface treatments, which can be beneficial in applications exposed to harsh environments.

- Hard and Brittle: Alnico magnets are hard and brittle, making them susceptible to chipping or breaking if mishandled. They cannot be drilled or machined using conventional methods, and any required shaping must be done before the magnetization process.

- Magnetic Orientation: These magnets can be magnetically oriented in the manufacturing process to enhance their magnetic performance in specific directions.

AlNiCo Magnets Applications

Alnico magnets are used in a wide range of applications, including:

- Electric Motors and Generators: Their ability to withstand high temperatures makes them suitable for various motor and generator applications.

- Sensors and Instruments: They are used in certain sensors, meters, and instruments where stable magnetic performance over a wide temperature range is required.

- Pickups for Electric Guitars: Alnico magnets are popular in the construction of pickups for electric guitars due to their specific magnetic field characteristics, contributing to the tone of the instrument.

- Loudspeakers and Microphones: Their magnetic properties are also advantageous in the design of loudspeakers and microphones.

AlNiCo Magnets Manufacturing

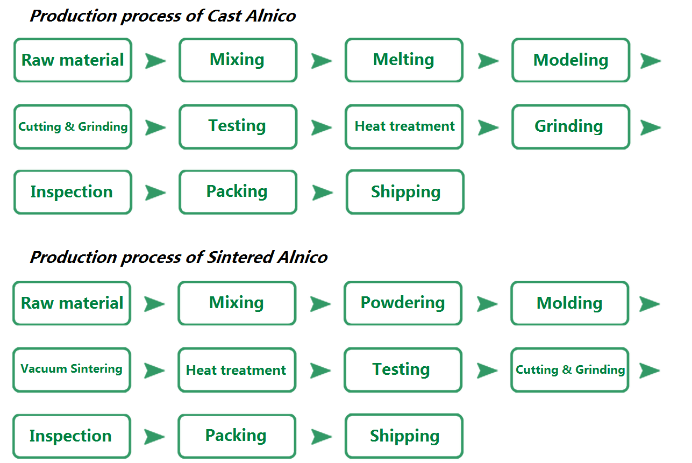

Alnico magnets can be made through either casting or sintering processes:

- Casting: The alloy is melted and poured into a mold, then cooled and solidified. Cast Alnico magnets can be produced in complex shapes and sizes but typically have rough surfaces.

- Sintering: Powdered Alnico is pressed into a die and then sintered in a furnace, bonding the particles together. Sintered Alnico magnets have better mechanical strength than cast magnets but are usually limited to smaller sizes.

Alnico magnets are alloys made of aluminum, nickel, cobalt, copper, iron, and other materials. They are divided into two types: cast Alnico and sintered Alnico, depending on the processing technology. They are widely used in aerospace, aviation, military, internal magnetic voltage and current meters, electronic energy meters, multimeters, flow meters, etc. They are also used in various magnetic sensors, polarized relays, temperature and pressure controllers, mobile phone buzzers, hearing aids, receivers, microspeakers, car ignition starters, car and motorcycle odometers, and more.

Cast Alnico magnets have higher magnetic properties and can be produced in various sizes and shapes. Sintered Alnico has a simpler process and can be directly pressed into the desired size. The advantages of Alnico magnets include low temperature coefficients, resulting in minimal changes in magnetic properties due to temperature variations. They can operate at temperatures up to 400 degrees Celsius and have strong resistance to moisture, oxidation, and good operational stability. Alnico magnets have strong corrosion resistance and do not require surface electroplating treatment.

Sintered Alnico uses the same materials as cast Alnico but is produced using powder metallurgy methods. It is suitable for producing products with complex, light, thin, and small shapes and is widely used in instruments, communication devices, magnetic switches, and various sensors.

Alnico magnets are ideal for corrosive and high heat applications up to 930°F (500°C).

Alnico magnets are commonly used for various types of sensors.

The Alnico Horseshoe Magnet has two magnetic poles close together. Ideal for school experiments and it makes a great gift. Includes a keeper to help retain magnetic power.

AlNiCo Magnets Properties and Characteristics

- High Magnetic Strength: Alnico magnets are known for their strong magnetic fields, although they are generally surpassed by rare earth magnets such as neodymium.

- High Temperature Resistance: One of the key advantages of Alnico magnets is their excellent ability to maintain magnetic strength at high temperatures, up to about 540°C (1000°F). This makes them suitable for applications where high temperature resistance is crucial.

- Corrosion Resistance: They exhibit good resistance to corrosion and typically do not require additional surface treatments, which can be beneficial in applications exposed to harsh environments.

- Hard and Brittle: Alnico magnets are hard and brittle, making them susceptible to chipping or breaking if mishandled. They cannot be drilled or machined using conventional methods, and any required shaping must be done before the magnetization process.

- Magnetic Orientation: These magnets can be magnetically oriented in the manufacturing process to enhance their magnetic performance in specific directions.

AlNiCo Magnets Applications

Alnico magnets are used in a wide range of applications, including:

- Electric Motors and Generators: Their ability to withstand high temperatures makes them suitable for various motor and generator applications.

- Sensors and Instruments: They are used in certain sensors, meters, and instruments where stable magnetic performance over a wide temperature range is required.

- Pickups for Electric Guitars: Alnico magnets are popular in the construction of pickups for electric guitars due to their specific magnetic field characteristics, contributing to the tone of the instrument.

- Loudspeakers and Microphones: Their magnetic properties are also advantageous in the design of loudspeakers and microphones.

AlNiCo Magnets Manufacturing

Alnico magnets can be made through either casting or sintering processes:

- Casting: The alloy is melted and poured into a mold, then cooled and solidified. Cast Alnico magnets can be produced in complex shapes and sizes but typically have rough surfaces.

- Sintering: Powdered Alnico is pressed into a die and then sintered in a furnace, bonding the particles together. Sintered Alnico magnets have better mechanical strength than cast magnets but are usually limited to smaller sizes.

Alnico magnets are alloys made of aluminum, nickel, cobalt, copper, iron, and other materials. They are divided into two types: cast Alnico and sintered Alnico, depending on the processing technology. They are widely used in aerospace, aviation, military, internal magnetic voltage and current meters, electronic energy meters, multimeters, flow meters, etc. They are also used in various magnetic sensors, polarized relays, temperature and pressure controllers, mobile phone buzzers, hearing aids, receivers, microspeakers, car ignition starters, car and motorcycle odometers, and more.

Cast Alnico magnets have higher magnetic properties and can be produced in various sizes and shapes. Sintered Alnico has a simpler process and can be directly pressed into the desired size. The advantages of Alnico magnets include low temperature coefficients, resulting in minimal changes in magnetic properties due to temperature variations. They can operate at temperatures up to 400 degrees Celsius and have strong resistance to moisture, oxidation, and good operational stability. Alnico magnets have strong corrosion resistance and do not require surface electroplating treatment.

Sintered Alnico uses the same materials as cast Alnico but is produced using powder metallurgy methods. It is suitable for producing products with complex, light, thin, and small shapes and is widely used in instruments, communication devices, magnetic switches, and various sensors.

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders