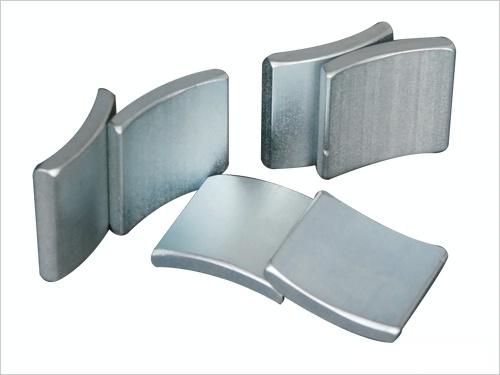

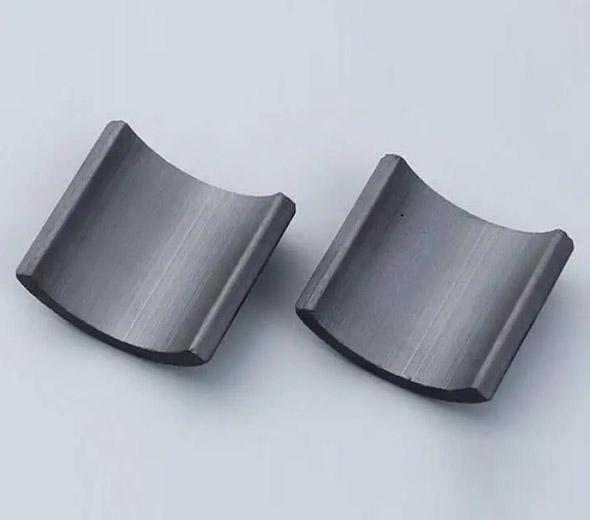

Block Ferrite Magnets

Block Ferrite Magnets are a type of permanent magnet that is highly efficient and cost-effective. Unlike other types of magnets in the market, our Block Ferrite Magnets are made from low-cost materials, iron oxide, and barium or strontium carbonates, which are readily available in the market.

PRODUCT INFORMATION

No tooling needed, we can cutting it according to your requirement.

Ferrite Magnet is a magnet compounded by magnetic powder and high polymer materials through the special craft.

It is superior to the sintered magnet in aspects of magnet shaping, size precision, flexibility etc. It may make the handed, circular, various geometric figures, sheet, coiled material (max. Width 780MM, thickness 0. 25-8MM, indefinite length ) according to the consumer’s requirements. Its surface may implement UV oil coating, spray lacquer, printing, lamination, double-faced adhesive tape, PVC processing and so forth. The products are widely applicable for the small-size precise motor, generator etc in aspects of the drive equipments; Loud-speaker, earphone, microphone, sound pick-up etc in aspects of the acoustic facilities; Relay, switch, sensor, instrument and meter and so no in aspects of the communication installation etc. The suction magnet is mainly used for the advertisement propaganda, electric refrigerator door sealing strip, toy and so forth. The correcting magnet is used in TV image tube, magnetic coupler, electronic lock etc.

Ferrite / Ceramic permanent magnets are technically known as hard ferrite materials (when exposed to a brief external magnetic field, the material retains magnetism due to having high coercivity, Hc). They are not the same as soft ferrite materials as used in transformer cores (which do not retain magnetism after exposure to a brief magnetic field because soft ferrite materials have low coercivity). The high coercive force of Ferrite Magnets means they are classified as hard materials, like all the other permanent magnets.

Ferrite magnets are extremely popular due to their characteristics. Ferrite magnets are corrosion free – for long term performance they are superb; if looked after they are capable of exceeding most products life-cycles. Ferrite magnets can be used up to +250 degrees C (and in some cases up to +300 deg C). Ferrite magnets are also low cost, particularly in high volume production runs. We offer 27 grades of ferrite permanent magnet.

Ferrite / Ceramic permanent magnets are technically known as hard ferrite materials (when exposed to a brief external magnetic field, the material retains magnetism due to having high coercivity, Hc). They are not the same as soft ferrite materials as used in transformer cores (which do not retain magnetism after exposure to a brief magnetic field because soft ferrite materials have low coercivity). The high coercive force of Ferrite Magnets means they are classified as hard materials, like all the other permanent magnets.

Ferrite magnets are extremely popular due to their characteristics. Ferrite magnets are corrosion free – for long term performance they are superb; if looked after they are capable of exceeding most products life-cycles. Ferrite magnets can be used up to +250 degrees C (and in some cases up to +300 deg C). Ferrite magnets are also low cost, particularly in high volume production runs. We offer 27 grades of ferrite permanent magnet.

Some of the benefits of our Block Ferrite Magnets include:

1. High Magnetic Strength

Our Block Ferrite Magnets have a high magnetic strength, which makes them efficient and effective in applications that require high flux density. This makes them the ideal product for a variety of applications in the automotive, industrial, and household equipment industries, among others.

2. Cost-Effective

One of the major benefits of our Block Ferrite Magnets is that they are highly cost-effective. As a manufacturer, we source our raw materials from reliable suppliers, and we have optimized our production process to ensure that our clients receive the best value for their money.

3. Resistance to Demagnetization

Our Block Ferrite Magnets are highly resistant to demagnetization, making them ideal for applications that require a long life span. Unlike other types of magnets, our Block Ferrite Magnets have a high coercivity, which ensures that they retain their magnetic strength even after exposure to high temperatures, mechanical shocks, and other adverse conditions.

4. Durability

Our Block Ferrite Magnets are highly durable, robust, and reliable, even in harsh environments. This makes them the ideal product for applications such as motors, generators, loudspeakers, and other electrical devices that require a high level of performance and reliability.

Applications

Our Block Ferrite Magnets are an essential product for a variety of applications, including but not limited to:

1. Electric Motors

Our Block Ferrite Magnets are commonly used in electric motors, which require a high level of efficiency and reliability. Our magnets ensure that the motors run smoothly and quietly, and the magnetic strength remains constant even in high temperatures and other adverse conditions.

2. Loudspeakers

Our magnets are also commonly used in loudspeakers, where they ensure that the sound quality is high and clear. They provide a stable magnetic field that ensures that the vibrations between the diaphragm and the coil are efficient and effective.

3. Generators

Our Block Ferrite Magnets are also commonly used in generators, where they ensure that the magnetism is constant, and the output is stable and efficient.

Professional in supplying magnetic materials, Genesis New Journey is one of the best suppliers in China. We have quality Block Ferrite Magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

We can provide

1. Best package: Any requirement for package can be satisfied.

2. Fast reply: All your inquiry will be replied within 24 hours.

3. Reasonable price: we are direct manufacturer and able to offer better price.

4. Good quality: we are experienced in quality control.

5. Full-way tracking the cargo for you before the goods arrive.

IN ORDER TO QUOTE YOU THE BEST PRICE, PLEASE PROVIDE US THE FOLLOWING INFORMATION.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

How do ceramic/ferrite block magnets compare to other types of magnets in terms of strength?

Ceramic/ferrite magnets have lower magnetic energy products compared to rare-earth magnets. However, their magnetic strength is adequate for many applications, especially where the highest magnetic force is not necessary, and cost or environmental resistance is a priority.

Can ceramic/ferrite block magnets be customized in size and shape?

Yes, these magnets can be customized to a wide range of sizes and shapes during the manufacturing process. The mixture of ferrite powder is pressed into molds before being sintered, which sets the final properties. Due to their brittleness, significant modifications after sintering are not recommended, although they can be cut or ground to size with appropriate tools.

How should ceramic/ferrite block magnets be handled and stored?

Handling: Despite their hardness, ferrite magnets are brittle and can chip or break if dropped or knocked together. Care should be taken during handling. Storage: No special requirements are necessary for storing ferrite block magnets. However, they should be stored in a way that prevents strong impacts or pressure that could cause damage.

Are ceramic/ferrite block magnets affected by temperature?

Ceramic/ferrite magnets can withstand high temperatures up to a certain point (typically up to 250°C or 482°F) before experiencing a permanent loss in magnetic properties. They are suitable for most applications where extreme temperatures are not a concern.

How are ceramic/ferrite block magnets manufactured?

The manufacturing process involves mixing ferrite powder with a binder, pressing the mixture into a mold to form the desired shape, and then sintering the pressed shape in a kiln at high temperatures. After sintering, the magnets are magnetized using a strong external magnetic field.

Can ceramic/ferrite block magnets be demagnetized?

While they are resistant to demagnetization, it is possible to demagnetize ceramic/ferrite magnets under extreme conditions, such as exposure to very high temperatures (above their Curie temperature), strong opposing magnetic fields, or physical shock. However, under normal conditions, they maintain their magnetism for a long time.

—————————————————————————————————————————————————————————————————————————-