AlNiCo Ring Magnet

Alnico ring magnets are a specific type of permanent magnet made from an alloy containing aluminum, nickel, cobalt, and often copper, and sometimes titanium or other elements. This composition gives them distinct properties that are advantageous in various applications.

AlNiCo Ring Magnet Description

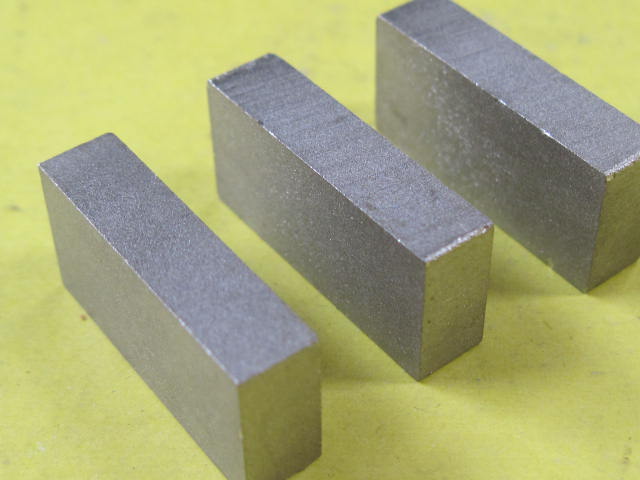

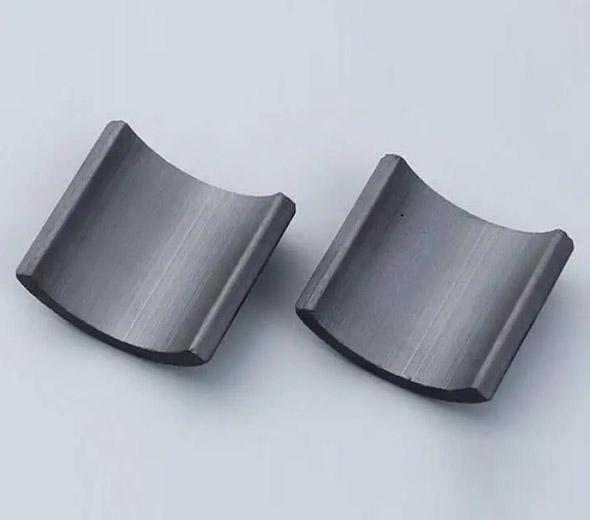

AlNiCo ring magnets are disc magnets with a plain hole through the center of the magnet. They are comprised of aluminum, nickel, cobalt, and iron with varying additions of other elements.

AlNiCo Ring Magnet Types

There are two different manufacturing processes for AlNiCo: Cast and sintered. Cast AlNiCo can be made into many sizes and shapes, whereas Sintered AlNiCo is usually restricted to smaller sizes. However, both processes lead to complex geometries and configurations. Standard Sintered AlNiCo has tighter dimensional tolerances due to its processing. It also has slightly lower magnetic properties, but better mechanical strength than Cast AlNiCo products.

Professional in supplying magnetic materials, Genesis New Journey is one of the best suppliers in China. We have quality Alnico ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

We can provide

1. Best package: Any requirement for package can be satisfied.

2. Fast reply: All your inquiry will be replied within 24 hours.

3. Reasonable price: we are direct manufacturer and able to offer better price.

4. Good quality: we are experienced in quality control.

5. Full-way tracking the cargo for you before the goods arrive.

IN ORDER TO QUOTE YOU THE BEST PRICE, PLEASE PROVIDE US THE FOLLOWING INFORMATION.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

What are Alnico ring magnets used for?

Alnico ring magnets are widely used in applications requiring a central hole for mounting or for focusing magnetic fields. Common applications include loudspeakers, sensors, magnetic bearings, various automotive components, and educational purposes to demonstrate magnetic fields.

How do Alnico ring magnets compare to other types of ring magnets?

Compared to ring magnets made from other materials like neodymium or ferrite, Alnico ring magnets offer superior thermal stability and resistance to corrosion but generally have a lower magnetic field strength. They are preferred in applications where high temperature and durability are critical.

What are the benefits of using Alnico ring magnets?

The main benefits include their ability to withstand high temperatures (up to 550°C), their resistance to demagnetization, and their durability in harsh environments. They are also versatile in their application due to their wide range of magnetic strengths and grades.

Can Alnico ring magnets be customized?

Yes, similar to other Alnico magnets, ring magnets can be customized in size and magnetic properties. The casting process allows for a variety of shapes and sizes, and the alloy composition can be adjusted to meet specific magnetic requirements.

How are Alnico ring magnets manufactured?

They can be manufactured through both casting and sintering processes. The casting process involves pouring molten Alnico alloy into a mold to achieve the desired shape. Sintering involves pressing Alnico powder into a compact form and then heating it below the melting point to fuse the particles. Casting provides greater magnetic strength, while sintering offers better mechanical strength and tolerances.

Are Alnico ring magnets prone to corrosion?

Alnico magnets, including ring types, exhibit good resistance to corrosion and do not typically require any surface treatments. However, in very harsh environments, some protective coating may be applied.

How should Alnico ring magnets be handled and stored?

They should be handled with care to prevent chipping or breaking, as Alnico is brittle. To avoid demagnetization, do not expose them to strong opposing magnetic fields and store them at room temperature. Using keepers (iron pieces that close the magnetic circuit) during storage is also advisable.

Can Alnico ring magnets be demagnetized and re-magnetized?

Yes, like other Alnico magnets, they can be demagnetized if exposed to sufficient heat or opposing magnetic fields. However, they can be re-magnetized back to their original magnetic strength by applying a strong magnetic field in the correct orientation.

What grades of Alnico are available for ring magnets?

Alnico ring magnets are available in various grades, from Alnico 1 to Alnico 9, with each grade offering different magnetic properties, including magnetic flux density and resistance to demagnetization. The choice of grade depends on the application’s specific requirements.

How do environmental factors affect Alnico ring magnets?

While Alnico magnets are generally very stable and resistant to environmental factors, extreme temperatures can affect their magnetic properties. They are designed to withstand high temperatures but can lose magnetization if heated above their Curie temperature. However, they are largely unaffected by humidity or other atmospheric conditions.

—————————————————————————————————————————————————————————————————————————-