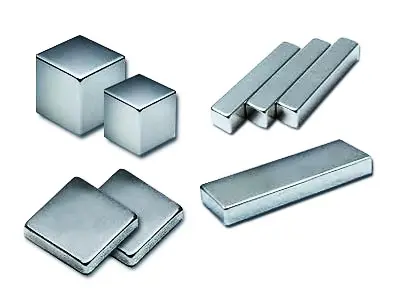

NdFeb Block Magnets

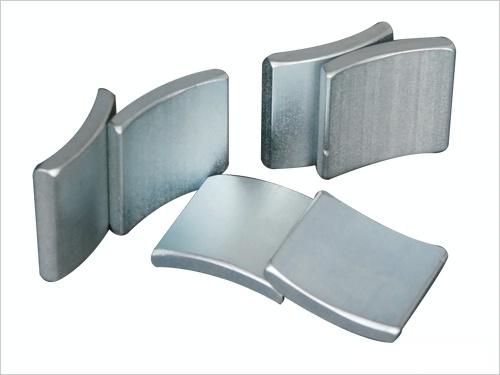

The ndfeb block magnets feature high coercivity, low reversible temperature coefficients and low weight loss. We can manufacture NdFeB products with low weight loss through continuous creation. So it can meet requirement of motor and other high-end field.

Product Description

NdFeb block magnets have high coercivity, low reversible temperature coefficient and low weight loss,moreover, feature excellent resistance to demagnetisation, coated with three layers of nickel, copper and nickel to reduce corrosion and provide a smooth finish. Through continuous creation, we can manufacture low-weight NdFeB products. Therefore, it can meet the needs of high-end fields such as motors. It provides greater flexibility for designing new or alternative traditional magnet materials such as ceramics, alnico, and samarium cobalt, enabling high-efficiency, low-cost, and more compact devices.

Our Neodymium magnets have many creative uses including model-making, theatre design, furniture making, exhibitions, retail displays and packaging. They also have many uses in engineering and manufacturing where small size and maximum strength are required.

What’s more, because of their resistance to demagnetisation they are ideal for creating a shock-absorbing or damping effect when used to repel other magnets. These magnets come with a safe-handling warning; because they are so powerful they can be dangerous if not handled carefully.

Neodymium Rectangular Magnets provided by us is carefully manufactured with the help of utmost grade components and advanced technology as per the industry set standards.

This ndFeb block magnet has a variety of uses. Because larger magnets have very high pull forces, they are favored in clamping applications, magnetic sweeper applications, and industrial applications, among others.

With the skills of our qualified professional team, we are committed to providing the highest quality range of NdFeB block magnets. These products are manufactured with high quality raw materials and advanced technology from our suppliers.

Features & Design

NdFeb Block Magnets are made from a unique blend of neodymium, iron, and boron (NdFeB), which is a type of rare earth magnet. The magnet is shaped like a rectangular block, which makes it easy to install and use in virtually any application. The size and strength of the magnet vary, depending on its intended use. However, all magnets are made to the same high-quality standard and come with a range of features that make them superior to other magnets on the market.

One of the most notable features of NdFeb Block Magnets is their strength. These magnets are incredibly powerful and can support a significant amount of weight. Depending on the size and strength of the magnet, it can hold up to 136 kg! This characteristic is especially useful in industrial, medical, and automotive applications, where heavy-duty magnets are required.

Another essential feature of NdFeb Block Magnets is their temperature resistance. These magnets can withstand high temperatures, making them perfect for use in extreme environments. They are also resistant to corrosion, which makes them ideal for use in harsh outdoor environments.

Applications

NdFeb Block Magnets are versatile and can be used for a wide range of applications, including:

1. Industrial Applications: NdFeb Block Magnets are commonly used in the manufacturing industry to hold metal parts in place during assembly. They are also used in automotive, aerospace, and robotics industries to create high-performance motors.

2. Medical Applications: NdFeb Block Magnets are used in medical devices such as MRI machines, drug delivery systems, and prosthetics.

3. Home and Office Applications: NdFeb Block Magnets can be used to hang artwork, organize cabinets and drawers, and secure doors and windows.

4. Energy Applications: NdFeb Block Magnets are used in renewable energy applications such as wind turbines and electric vehicles.

ADVANTAGES

NdFeb Block Magnets offer many advantages to businesses and individuals who use them. Here are some of the key advantages:

1. Cost-Effective: NdFeb Block Magnets are an affordable and cost-effective solution compared to other magnetic materials.

2. High-Performance: NdFeb Block Magnets are more powerful and have a higher magnetic flux density than other magnetic materials.

3. Longevity: NdFeb Block Magnets are resistant to corrosion and have a long lifespan.

4. Safe to Use: NdFeb Block Magnets are safe to use when handled and installed correctly, and they do not pose any health risks.

NdFeb Block Magnets are a versatile, cost-effective, and powerful magnetic material that offers many benefits to businesses and individuals in the manufacturing, medical, energy, and home applications. Their unique blend of neodymium, iron, and boron make them superior to other magnetic materials on the market, and their strength and resistance to corrosion make them ideal for use in harsh outdoor environments. As a supplier, I highly recommend NdFeb Block Magnets to businesses looking for a reliable, high-performance, and cost-effective solution for their magnetic material needs.

Professional in producing ndfeb magnets, Genesis New Journey is one of the best suppliers in China. We have quality ndfeb ring magnets for sale. Please feel free to contact us.

Looking for a certain size? If you require a specific size that is not available on our website, please contact us for a custom magnet quote.

| Material | Neodymium-Iron-Boron | |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| N35M- N50M | 100°C (212°F) | |

| N35H-N48H | 120°C (248°F) | |

| N35SH-N45SH | 150°C (302°F) | |

| N28UH-N40UH | 180°C (356°F) | |

| N28EH-N38EH | 200°C (392°F) | |

| N28AH-N35AH | 220°C (428°F) | |

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.Customized shapes for Sintered Neodymium Strong Magnets are available. | |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Phosphating, Chemical, PTFE, ParyleneEverlube, Passivation and more. | |

| Magnetization Direction | a. Thickness Magnetizedb. Axially Magnetizedc. Diametrally Magnetizedd. Multi-poles magnetizede. Radial Magnetizedf. Customized specific requirements magnetized | |

| Delivery Time | The lead time around 10-25days | |

| Payment Terms | L/C,T/T,Paypal, ESCROW, Western Union | |

Surface Treatment of NdFeB magnet

NdFeB magnets are susceptible to corrosion, so it is necessary to give surface treatment Currently, the surface treatments mainly includes chemical plating, conversion coating and coating. In most cases, NdFeB magnet surface are treated with NiCuNi (Nickel-Copper-Nickel) plating, Zinc plating and Epoxy coating. For special requirements, passivation and phosphatization are also adopted.

| Plating Instructions | ||||

| Type | Coating | Thickness | Color | SST(Hours) |

| Nickel | Ni+Cu+Ni | 10~20 μm | Bright Silver | 24~72 |

| Black Nickel | Ni+Cu+Black Ni | 10~20 μπ | Bright Black | 48~96 |

| Cr3+Zinc | Zinc | 5~8μm | Blue white | 16~48 |

| Color Zinc | 5~8μm | Colorful | 36~72 | |

| Sn | Ni+Cu+Ni+Sn | 10~25μm | Silver | 36~72 |

| Au | Ni+Cu+Ni+Au | 10~20 μm | Gold | 12 |

| Ag | Ni+Cu+Ni+Ag | 10~20μm | Silver | 12 |

| Epoxy | Exopy | 10~20μm | Black/Grey | 48 |

| Ni+Cu+Epoxy | 15~30μm | 72~108 | ||

| Zn+Epoxy | 15~25μm | 72~108 | ||

| Passivation | //// | 1~3μm | Dark Grey | temporary protection |

| Phosphatization | //// | 1~3μm | Dark Grey | temporary protection |

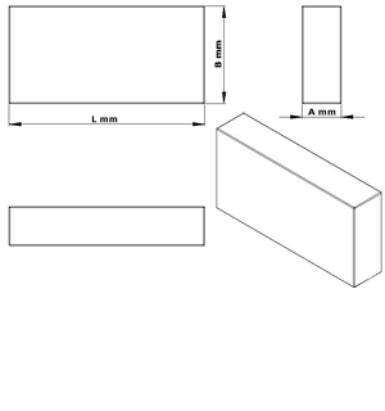

In order to quote you the best price, please provide us the following information.

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| L: length. W: width, T: thickness, D: diameter, OD: outer diameter, ID: inner diameter.For other shapes, please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other ? | ||

| Working Temperature | Normal or High temperature ? | ||

· Customized is Available

· Affordable price

· Quality guaranteed

· T/T and XTranfer accepted

· Other payment accepted

· Fast shipping, Worldwide delivery

· excellent customer service

· Offer free magnetic solution

· Bulk discounts for larger orders

FAQ

What is a neodymium magnet?

A neodymium magnet is a type of rare-earth magnet that is made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. It is the strongest type of permanent magnet commercially available.

How strong are neodymium magnets?

Neodymium magnets are extremely strong for their size. They can lift thousands of times their own weight. The exact strength depends on the grade of the magnet, which can vary based on the manufacturing process.

What are the grades of neodymium magnets?

Neodymium magnets come in different grades, such as N35, N42, N52, etc. These grades indicate the strength of the magnet. The higher the number, the stronger the magnet. Grades may also include letters after the number indicating temperature resistance.

Can neodymium magnets be demagnetized?

Yes, like all permanent magnets, neodymium magnets can be demagnetized if exposed to high temperatures (above their Curie temperature), strong demagnetizing magnetic fields, or if they are physically damaged.

Are neodymium magnets dangerous?

Neodymium magnets can be dangerous if not handled properly due to their strong magnetic force. They can snap together with great speed, potentially causing injuries or damaging the magnets. Small magnets also pose a swallowing hazard, which can be life-threatening.

How do I separate two neodymium magnets?

Separating neodymium magnets, especially strong ones, can be challenging. It’s often recommended to slide them apart rather than trying to pull them directly apart. Using a piece of plastic or wood as a lever can also help. Always wear protective gloves to avoid pinching.

Can neodymium magnets affect electronic devices?

Yes, due to their strong magnetic fields, neodymium magnets can affect or damage sensitive electronic devices, such as smartphones, magnetic storage media like hard drives, and credit cards. Keep them at a safe distance from such devices.

How long do neodymium magnets last?

Neodymium magnets can last for decades if they are kept in optimal conditions, not exposed to high temperatures, strong external magnetic fields, or physical damage.

Can neodymium magnets be cut or drilled?

Neodymium magnets are very hard and brittle, making them difficult to cut or drill. Doing so requires special tools and techniques, and it should be done with caution to avoid cracking or shattering the magnet, as well as to protect from potentially hazardous dust.

How are neodymium magnets made?

Neodymium magnets are manufactured through a complex process that includes melting the raw materials (neodymium, iron, and boron), casting them into ingots, pulverizing the ingots into powder, pressing the powder in a magnetic field to align the particles, sintering the pressed compact to fuse the particles, and then machining and coating the magnets to protect them from corrosion.

—————————————————————————————————————————————————————————————————————————-